The Epsilon team continues to see an increasing demand for manufacturing capacity in North America as companies look to move production of critical components from overseas to the US, Canada, and Mexico. While pharmaceutical companies and electric vehicle component manufacturers were early adopters in response to COVID-19 and rapidly growing markets, other verticals are now joining the movement to increase US production capabilities.

In general, the move to onshoring includes a push for rapid ramp-up and increasing construction efficiency at every opportunity. Suppliers know they need to be nimble and adjust to changing demands as part of the multi-industry drive for on-shoring and near-shoring. Standing up new manufacturing facilities for high-demand products is crucial to support fast-growing market segments. That’s where Off-Site Construction (OSC) shines, and is playing an ever-growing role in the manufacturing sector.

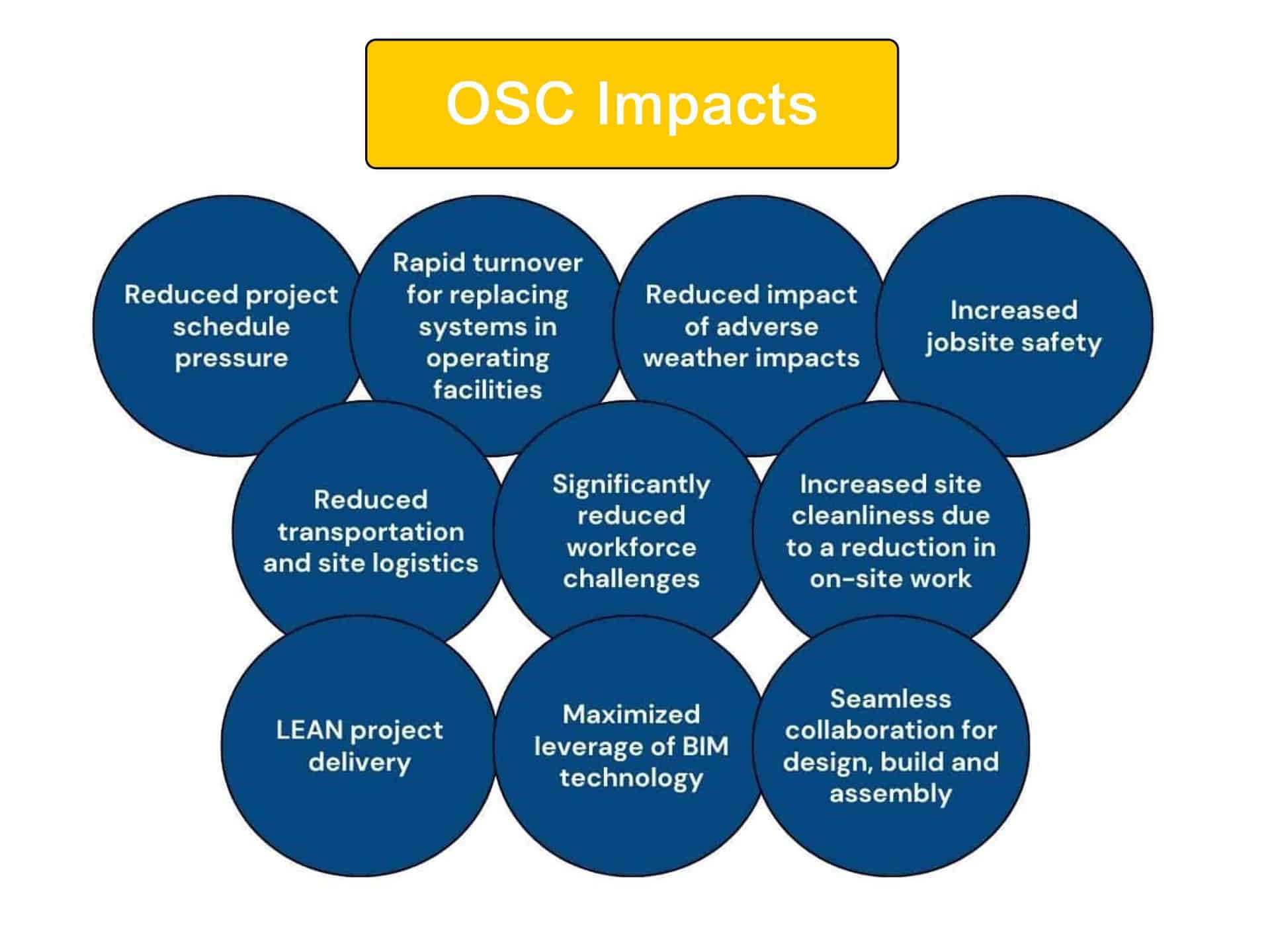

Here are a few reasons why our clients have chosen OSC as a key element of their expansion plans:

Reduced Construction Time – Modular, prefabricated construction techniques reduce overall construction time. OSC allows central plant facilities to be manufactured while other construction efforts occur in parallel, reducing the overall construction timeline and minimizing schedule disruptions that arise from on-site conditions.

Budget and Scope Management – Off-Site Construction is a leading contributor to streamlined budget and scope management, particularly for the complex mechanical systems found in Central Utility Plants (CUP). Engaging an expert in OSC provides construction teams with accurate budgets very early in the process – and those budgets can then be managed very closely through continued engagement of the OSC experts, particularly for teams that utilize the Design Assist approach.

Risk Reduction – Using OSC helps reduce risks that stem from a variety of issues, including labor availability and cost variability, material supply chains, weather delays and site readiness.

Cost Certainty – OSC removes variables that can cause costs to increase once the project is approved, giving owners and constructors confidence that the modular units will be delivered at the price quoted.

Lean Construction – When OSC is properly leveraged, schedules can be compressed, performance improved, and risk mitigated – all while simultaneously optimizing costs. This includes utilizing alternative delivery methods, earlier decisions and the benefits of experienced partners.

These are just a few examples of areas in which OSC is having a tremendous impact on the projects that elect to utilize it. If your team isn’t already exploring Off-Site Construction for projects, be sure to talk with the Epsilon experts to learn more.