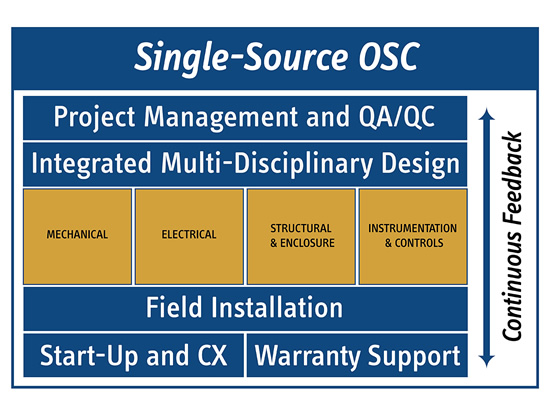

Off-Site Construction (OSC) is the preferred choice for building owners and construction teams that desire plant systems that are assembled in a controlled factory environment to exacting standards. OSC plants are fully inspected, bench tested and validated at the factory before shipping, which ensures a smooth startup and reduced commissioning times.

Off-Site Construction (OSC) is the preferred choice for building owners and construction teams that desire plant systems that are assembled in a controlled factory environment to exacting standards. OSC plants are fully inspected, bench tested and validated at the factory before shipping, which ensures a smooth startup and reduced commissioning times.

Utilizing Epsilon’s custom OSC approach delivers complex systems with limitless configurations and turnkey field installation by Epsilon or a third-party provider.

Why Choose Off-Site Construction?

Our end-user owner and construction company clients choose Epsilon custom off-site construction because of the positive impact on critical project considerations, including: