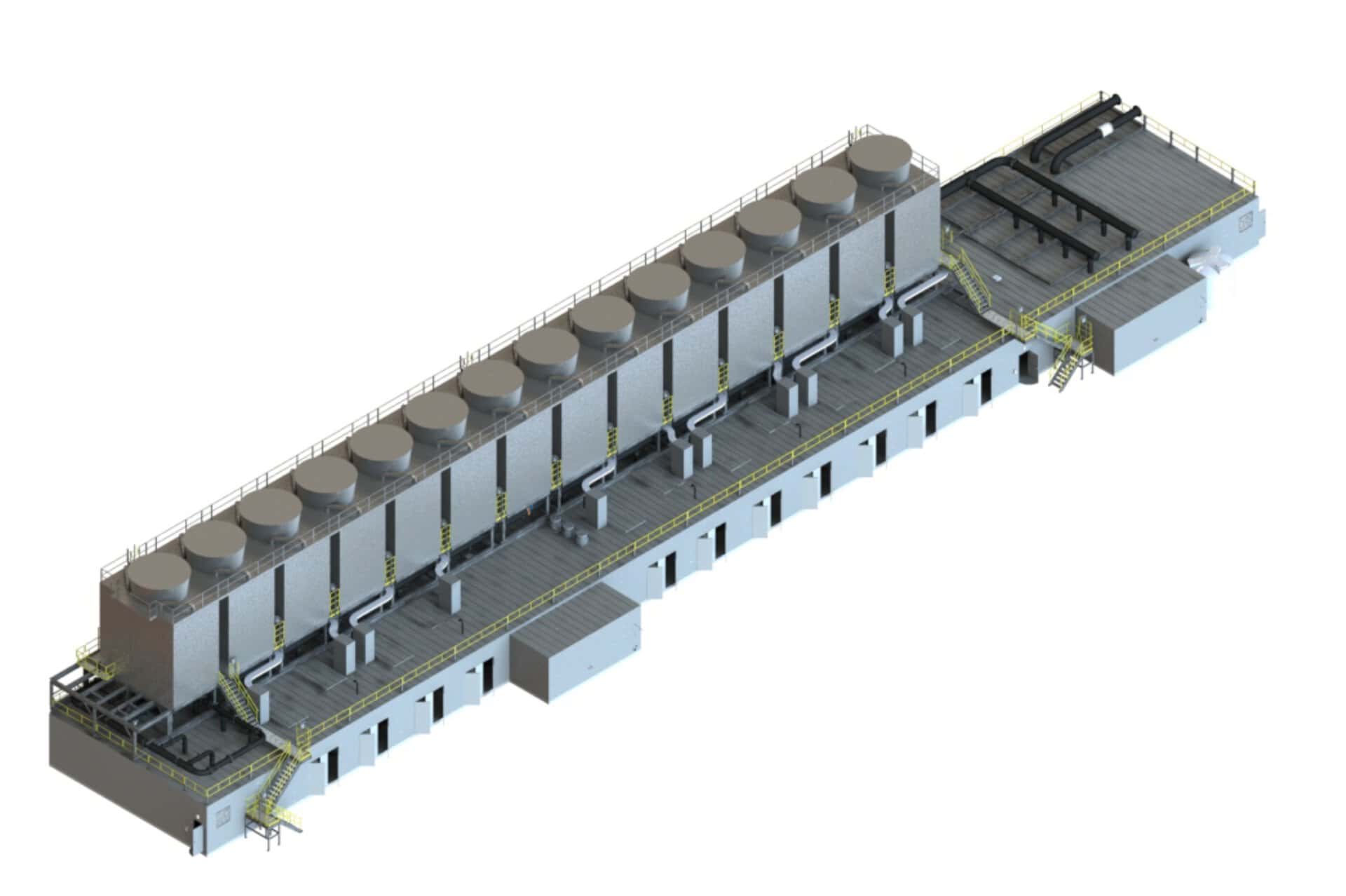

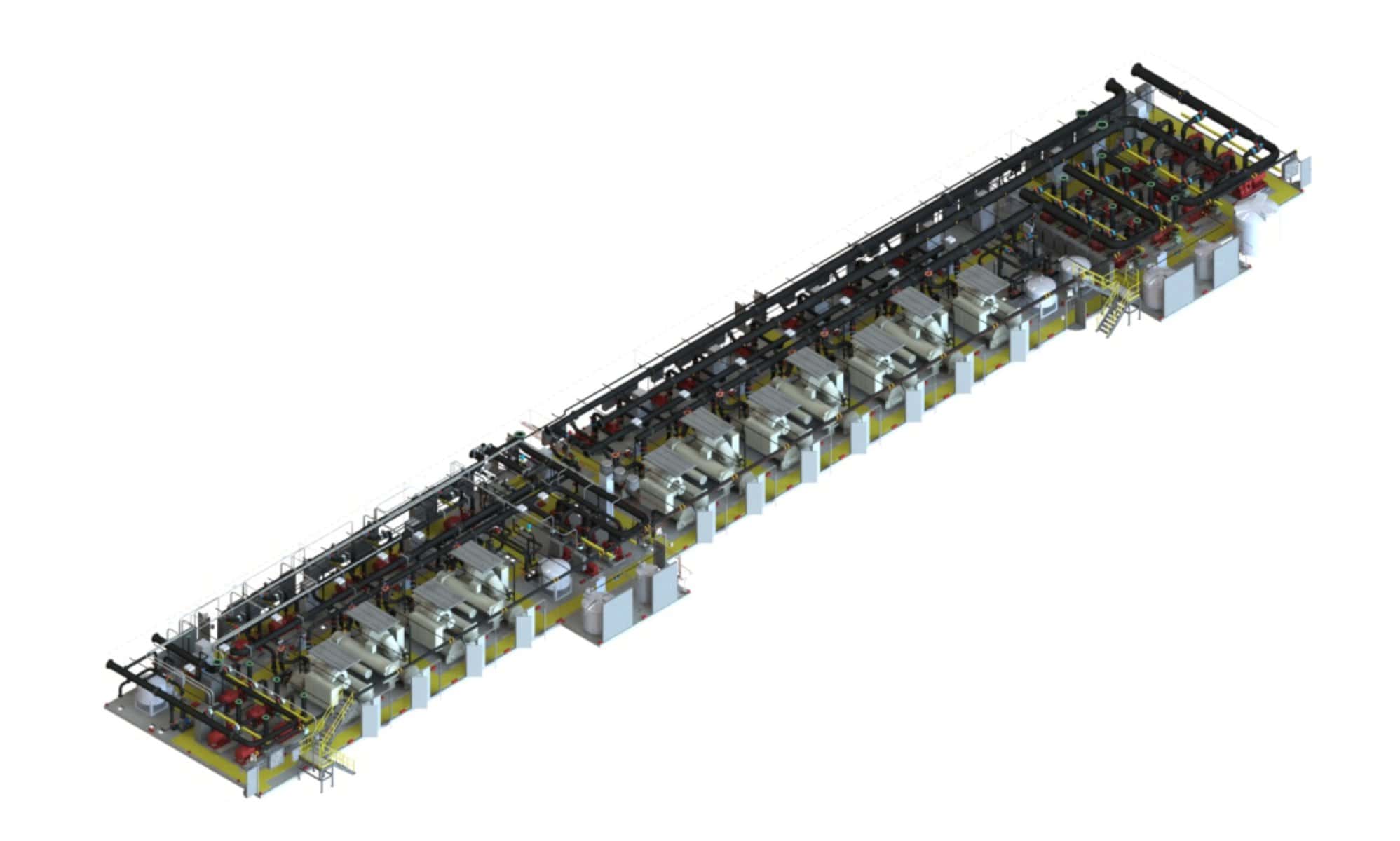

Epsilon was recently awarded a project for a 15,000-ton multi-stage chilled-water plant for an industrial client in the upper Midwest region of the US.

Project sub-systems include:

- 4 x 1100-ton low temp (39°F) chillers

- 7 x 1450-ton process (49°F) chillers

Epsilon’s engineering group engaged early with the multidisciplinary project team in a Design Assist phase to closely coordinate the sizing and configuration of the chilled-water systems with the evolving manufacturing loads to optimize lifecycle cost, delivery schedule and operating flexibility.

By selecting Off Site Construction for these critical systems, the project team was able to take advantage of the collaborative Design Assist approach, while also helping to manage the risk of an aggressive site schedule and the projected scarcity of traditional field labor.