If the past year has taught us anything, it is the importance of balancing flexibility with preparation and well-developed processes. For many in the construction industry, 2020 and the first half of 2021 involved massive changes, including adapting to travel restrictions, labor impacts, supply chain challenges and tasks normally handled in person with paper, like design sessions and constructability reviews.

If the past year has taught us anything, it is the importance of balancing flexibility with preparation and well-developed processes. For many in the construction industry, 2020 and the first half of 2021 involved massive changes, including adapting to travel restrictions, labor impacts, supply chain challenges and tasks normally handled in person with paper, like design sessions and constructability reviews.

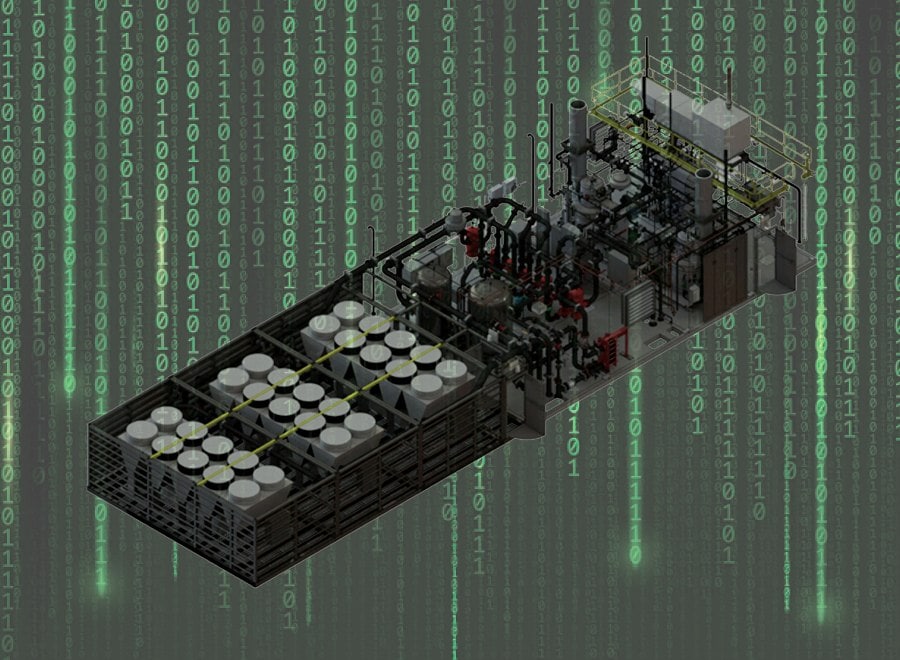

A common theme in this balancing act was pivoting to digital workflows, and that’s an area where Epsilon shines. We have been utilizing digital workflows for projects across North America for years – the processes involving remote project coordination and management are uniquely suited to experienced off-site construction manufacturers and installers. We have decades of experience working on long-distance projects, when modular elements need to arrive on time, ready to assemble with minimal on-site work.

While Epsilon was already at the forefront of digital workflows, we leaned into the opportunity to refine and improve our approach. We expanded our use of Building Information Modeling (BIM) and implemented new procedures to improve overall project speed and efficiency, while maintaining our reputation for high levels of quality. Our team also gained new insights into helping customers and construction partners adapt to digital workflows, sharing our knowledge and best practices for the betterment of a variety of projects.

Digital workflows and BIM are here to stay, and Epsilon is proud to be a leader in this space, particularly when applied to off-site construction and designing and implementing complex modular systems. If you are considering a central utility plant or similar infrastructure and would like to capitalize on the benefits inherent with digital workflows, get in touch and let’s talk about your project.