Challenge:

Holy Cross Health planned to construct a new hospital facility that would include a full-service emergency department, maternity ward, surgical services, and psychiatric care – along with an adjacent medical office building. The 6-story, 237,000-square-foot, 78-bed facility would be the first new hospital in Montgomery County, MD in over 35 years. But with so many patient-related demands on the project’s allowable square footage, the project team was challenged to find enough space for the myriad of central utility plant (CUP) heating and cooling systems. Bottom line: any space provided for chillers or boilers would mean a loss of space available for critical patient care services.

Solution:

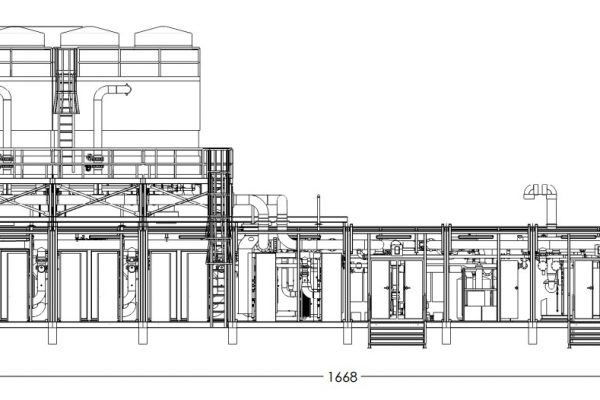

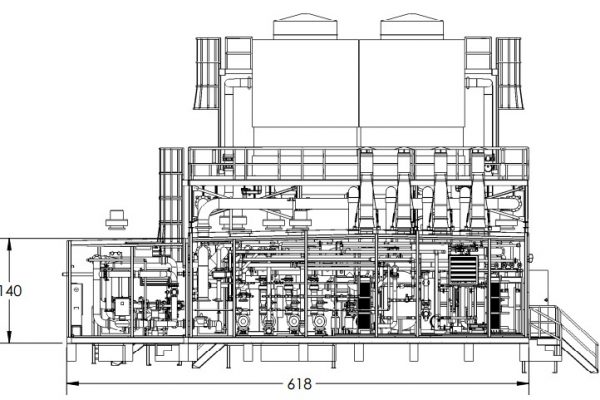

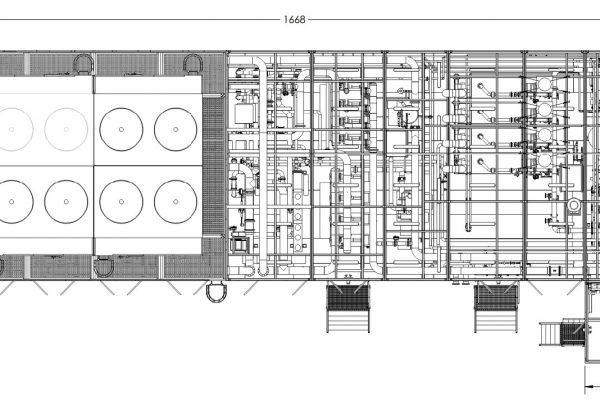

To address that challenge, the project team chose the Off-Site Construction (OSC) approach. Epsilon was selected and engaged early in the conceptual design process to help develop – in collaboration with the owner, engineer and construction manager – the best path to meet the project’s CUP needs in a way that would meet the stringent demands of a 24/7 hospital. Through a collaborative process, the team developed a 5,000 sq. ft. free-standing modular CUP consisting of:

- 2,000 tons chilled water (water cooled) with magnetic bearing chiller technology

- 16 MMBTUH hot water utilizing premium-efficiency dual-fuel (oil/NG) condensing boilers

- Integral electrical switchgear and distribution

- Stand-alone PLC controls for CUP by Epsilon, integrated closely with the hospital’s BMS for regular monitoring and control by facility staff

One innovative aspect of the project was utilization of water-to-water heat-pump-style chillers to meet part of the total chilled-water load. In concert with the dual-fuel boilers, this provides hospital facility staff with the ability to generate hot-water using three sources of energy – oil, natural gas, or electricity.

Additionally, Epsilon’s full enclosure (not just the base) is structurally rated, enabling the project team to easily and cost-effectively locate the cooling towers on the roof of the plant, without extensive additional steel support systems. This helped limit the amount of valuable site area required for the CUP.

Because the modular CUP was ETL-listed as a factory-fabricated unit, it was considered to be a piece of equipment, rather than occupiable square-footage. This classification enabled the client to use that equivalent space in ways that more directly impacted patient care.

Project Overview

Client: Holy Cross Health

System Type: Central Utility Plant (CUP) – Chilled Water and Hot Water

Market Sector: Healthcare