There are multiple considerations that go into designing and building complex mechanical systems. When it comes to Off-Site Construction (OSC), designers must consider, and overcome challenges that are unique to modular building — challenges that ultimately enhance the overall finished system.

Here are three examples the Epsilon team routinely addresses:

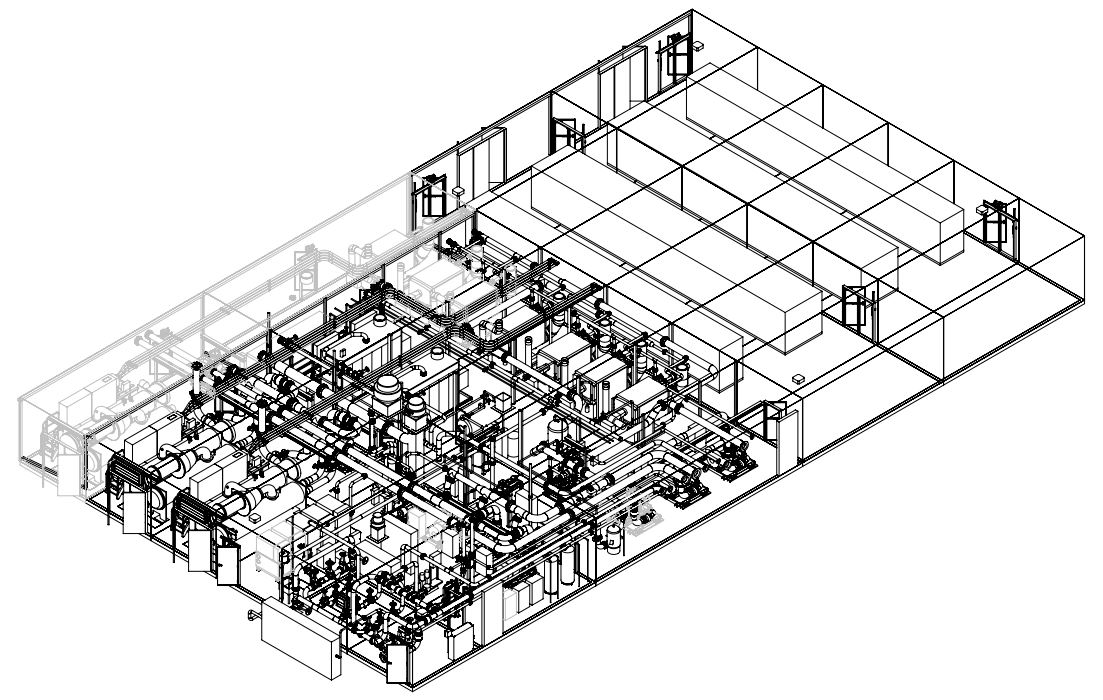

Designing for Space Optimization: One of the lesser-known benefits of working with an experienced OSC manufacturer like Epsilon is the incredible efficiencies in system layout and design. By their very nature, modular systems utilize a more efficient design approach.

Not to be confused with “compressing” or “compacting,” OSC designers optimize for the most efficient utilization of available space. This engineering work is done with multiple considerations in mind – not simply fitting equipment into an available space. These include maintenance and repair and a smaller systems footprint, among others.

Designing for Safety: Despite the construction industry’s growing adoption of OSC for utility systems, there remains a slowly disappearing perception that prefabrication and modular construction lead to compromised safety. These beliefs often stem from prefabrication methods that support piping and equipment from the floor, creating a complex web of vertical supports that limit movement and access throughout the system.

The Epsilon design and manufacturing teams builds structurally rated systems that enable piping and other components to be hung from the ceiling. Structurally rated enclosures have other unrelated downstream benefits, such as easier installation due to roof-mounted lifting lugs in lieu of base-mounted ones and a corresponding reduction in field labor required to mount cooling tower assemblies. In addition, our team gets involved early in the process, in part to have a better understanding of client requirements.

For example, a recent client communicated early on that they see significant time, safety, and operational cost savings by eliminating the need for maintenance lifts. In response, the Epsilon team helped develop integral access platforms within the OSC plant to facilitate regular maintenance without the need for ladders or fall protection.

Designing for Shipping:  Shipping complexities and demands are major factors in the overall success of an Off-Site Constructed system. It requires an experienced engineering team that can incorporate the demands of shipping into every design since the forces exerted on modular package components as they are shipped at highway speeds can easily exceed those experienced during a typical seismic event. Epsilon’s engineering team takes those stresses into account when planning how equipment, piping and conduit are supported and secured within each module.

Shipping complexities and demands are major factors in the overall success of an Off-Site Constructed system. It requires an experienced engineering team that can incorporate the demands of shipping into every design since the forces exerted on modular package components as they are shipped at highway speeds can easily exceed those experienced during a typical seismic event. Epsilon’s engineering team takes those stresses into account when planning how equipment, piping and conduit are supported and secured within each module.

One ancillary benefit of a system purpose-built for shipping is that it’s far more robust than the traditionally built, field-assembled equivalent. This contributes to the inherent longevity of any system that is provided using the OSC approach.

Of course, there are a myriad of other design considerations that are part of a successful OSC build and installation. The three referenced here are typically less visible to clients yet become critical to the overall project success and the central utility plant lifecycle. If you’re considering a central utility plant for new construction or a retrofit, be sure to talk with the Epsilon team early in the process. A little extra time during the project planning phase can yield significant benefits years after the project is completed.