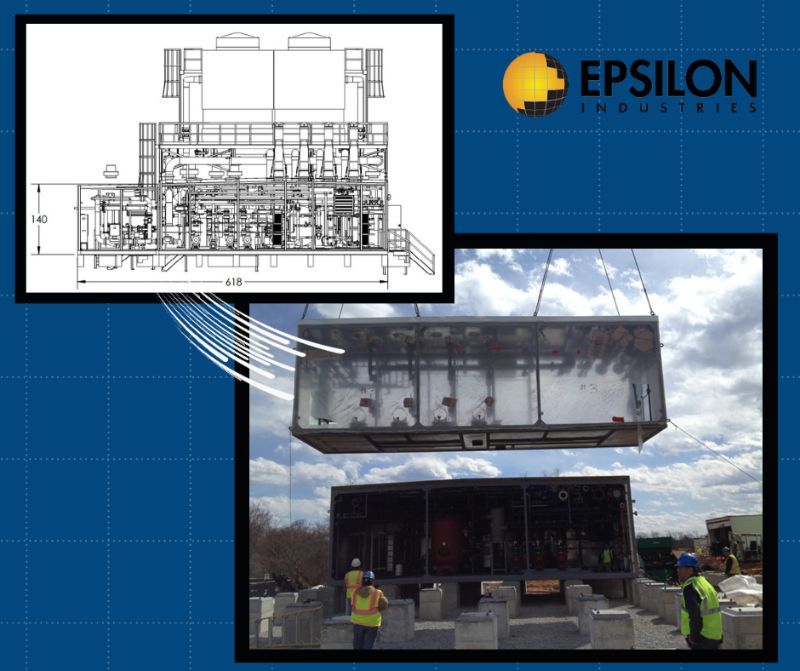

As a leading designer and constructor of highly customized packaged mechanical and electrical utility systems, we know project teams want a solution that is better, faster and easier. This is particularly evident in fast-to-market industries that benefit from quickly ramping up new production and manufacturing facilities. We hear three primary reasons why these teams lean into the Off-Site Construction (OSC) approach:

As a leading designer and constructor of highly customized packaged mechanical and electrical utility systems, we know project teams want a solution that is better, faster and easier. This is particularly evident in fast-to-market industries that benefit from quickly ramping up new production and manufacturing facilities. We hear three primary reasons why these teams lean into the Off-Site Construction (OSC) approach:

Compressed Schedules – as part of the multi-industry drive to on-shoring and near-shoring, suppliers increasingly need to be nimble and adjust to changing demands. Standing up new manufacturing facilities for high demand products, such as electric vehicle batteries or pharmaceuticals is crucial for fast-growing market segments. Off-Site Construction (OSC) allows central plant facilities to be manufactured in parallel with other construction efforts, reducing the overall construction timeline and minimizing schedule disruptions due to on-site conditions.

Cost Certainty – OSC often provides cost savings compared to traditional on-site construction methods. However, the bigger value delivered by OSC is in cost certainty – removing variables that can cause costs to increase once the project is approved, giving owners and constructors confidence that the modular units will be delivered at the price quoted.

Lean Construction – At a high level, the goal of Lean Construction is to minimize material waste, time and effort in order to maximize value to the customer. When OSC is properly leveraged, schedules can be compressed, performance can be improved, and risk can be mitigated – all while simultaneously optimizing costs.

Regardless of the reason, companies turn to Epsilon because of our two-decades-plus experience in OSC, particularly in serving fast-to-market industries. Contact our team today to discuss your next project.