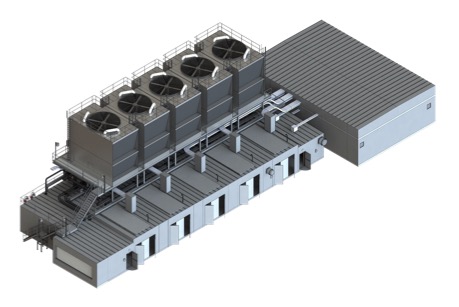

Epsilon is pleased to announce it is providing a chilled water plant that will deliver seasonal cooling for a major automotive manufacturer’s production plant in the Central U.S. This fully-integrated, offsite-constructed system will provide 7,500 tons of chilled water from five Trane centrifugal chillers, and includes a full substation to feed all equipment to this assembly plant. The chiller plant is engineered for maximum energy efficiency with features that include variable speed drives on all chillers, pumps, and fans, with fully automatic operation under all conditions.

The project team chose a modular, prefabricated chilled water plant over the traditional field-built approach because it provides superior cost certainty, schedule surety and overall risk management.

Like all Epsilon packaged utility systems, this plant is engineered to provide optimum safety throughout the system lifecycle including both construction and operation phases; once installed, operating personnel have no need to climb or utilize fall protection for any routine task. For example, chemical treatment is provided from a dedicated fork-accessible module that includes multiple spill containment chambers and avoids all manual handling of drums or totes.

This Epsilon modular chilled water system is an integral part of a larger project being provided by Walbridge as the general contractor, with engineering services from Affiliated Engineers (AEI) and controls by Leidos. Epsilon’s integration partner on this project is Climate Technologies.